Host materials

Optical telecommunication-grade fibers are made usually from silica glasses. The

high purity glass is called the host material or substrate. Its bulk refractive index

usually defines the refractive index of the fiber cladding. Adding dopant materials to

the host material forms the fiber core.

Dopant materials

To change the refractive index of optical fiber, pure silica is often doped with dopants.

For example, adding germanium can result in an increase in the refractive index,

while adding fluorine reduces it. The refractive index of doped material can be

determined by the linear relationship between the doped material’s mole percentage

and permittivity.

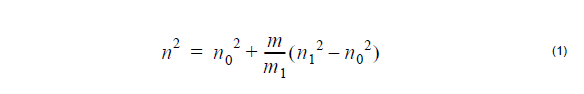

Aumme that n0 is the refractive index of the host material and n1 is the refractive index

of m1 molepercentage doped material. Then, the refractive index n of m molepercentage

doped material can be interpolated as:

The radial distribution of the fiber refractive index is called the index profile. That

The radial distribution of the fiber refractive index is called the index profile. That

profile determines guiding properties of the fiber. In general, the core region has a

higher index than the cladding region. However, the index profile can have regions

where the index is lower than the cladding value. Modern fiber designs are based on

index profiles that assure proper operation within a range of wavelengths.

For example, a dispersion flattened fiber design involves a couple of concentric index

regions.

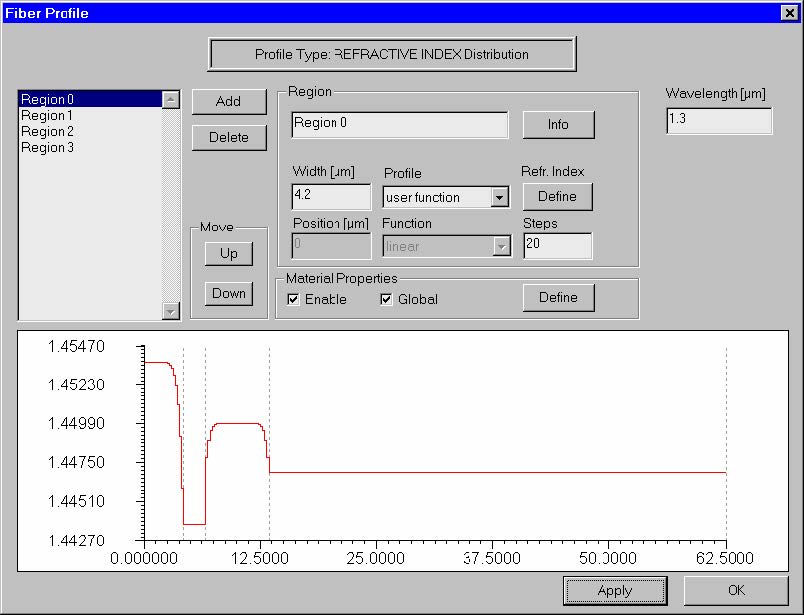

In OptiFiber “regions” define a rotationally symmetric fiber profile. In the picture

above, the fiber profile consists of four regions. Each region has its dimension (width)

and profile. The default profile options are listed below, where x is the region’s local

coordinate, w is the width of the region.

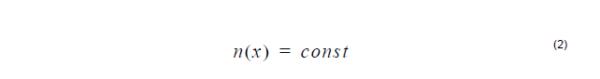

Constant profile: Linear profile:

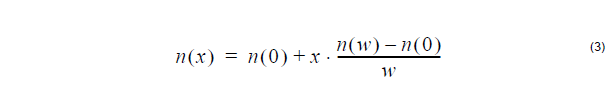

Linear profile:

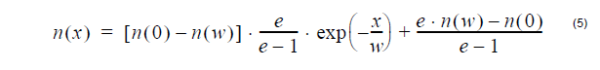

where n(0), n(w) is the refractive index at x = 0 and x = w, respectively.

where n(0), n(w) is the refractive index at x = 0 and x = w, respectively.

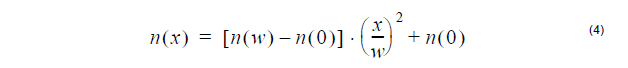

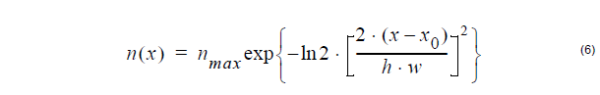

Gaussian profile:

where nmax is the maximum value, x0 is the peak position, and h is the

where nmax is the maximum value, x0 is the peak position, and h is the

normalized value of FWHM.

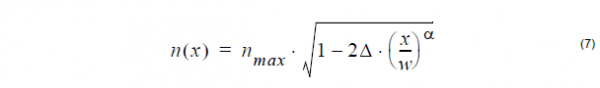

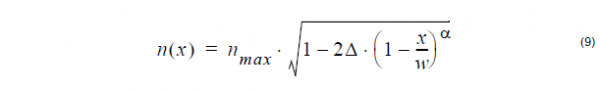

Alpha –peak profile:

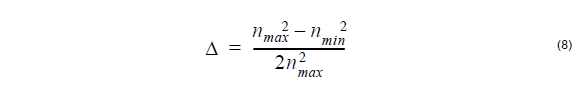

where nmax is the maximum value, Δ is normalized difference. It is defined as:

where nmax is the maximum value, Δ is normalized difference. It is defined as:

where nmax is the maximum value, Δ is normalized difference.

where nmax is the maximum value, Δ is normalized difference.

Two techniques for defining the refractive index profile

Currently OptiFiber implements two methods for defining the geometry and the

material composition of the fiber:

- Direct definition of the refractive index profile: the abscissa values n(x) in the

formulae above are interpreted directly as refractive index values at a user

specified wavelength. Wherever needed, the dopant concentration in each region

is internally calculated by interpolating the given value between the refractive

index values of two materials – “Dopant +” and “Dopant -” and using the formula

given in “Dopant Materials”. The material dispersion and dispersion of the profile

are calculated from the known Sellmeier coefficients of “Dopant +” and “Dopant –

”. The parameters of the materials “Dopant +” and “Dopant -” are either taken from

the internal extendable material library of OptiFiber or user specified. They can

be different for each region or global for the whole profile. This method is

convenient whenever the distribution of the refr. index is known from experimental

measurements, estimations, etc. - Definition of a dopant concentration profile: the abscissa values n(x) in the

formulae are interpreted as molar concentration of a certain dopant. The material

dispersion and dispersion of the profile are calculated from the known Sellmeier

coefficients of the dopant, which are taken from the internal extendable material

library of OptiFiber or are user specified.

This method is convenient when the dopant concentration distribution of the fiber or

at least of its preform are known with sufficient accuracy.