Temperature and strain change the grating period as well as the grating refractive

index. Consequently, the response of the grating device is changed when

temperature and strain distributions change.

Strain-optic effect of fiber Bragg grating

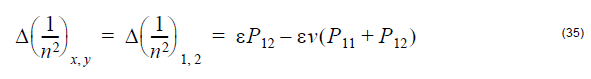

The changes of optical indicatrix caused by strain are:

where, ε1 = ε2 = –vε, ε3 = ε, ε4 = ε5 = ε6 = 0 (no shear strain), and ε

being the axial strain in the optical fiber. The symbol v denotes the Poisson’s ratio

for the fiber.

The strain-optical tensor for a homogeneous isotropic material is:

where Pij are the strain-optic constants,

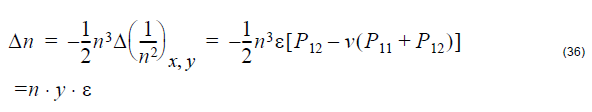

The refractive index change is:

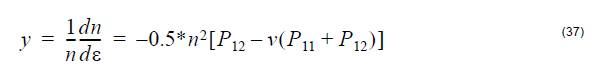

where the strain-optic coefficient y is defined as:

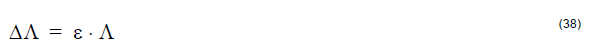

The grating period changes is:

The default strain distributions that can be applied to a fiber grating are listed below:

- Uniform

where ε0 is the constant strain.

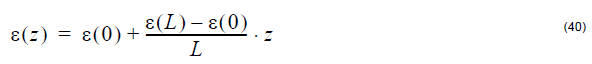

- Linear

where L is the grating length, ε(0) is the strain at z = 0, and ε(L) is the strain

at z =L

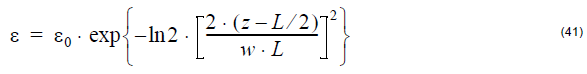

- Gaussian

where ε0 is the peak strain value and w is the normalized value of FWHM.

Other strain distributions can be defined by user functions.

Thermal-optic effect of fiber Bragg grating

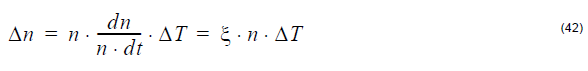

The temperature-induced refractive index change is:

where ξ is the thermo-optic coefficient of the fiber and ΔT is the temperature

change.

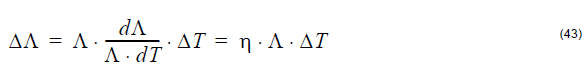

The temperature-induced grating period change is:

where η is the thermo-optic expansion coefficient.

The default temperature distributions that can be applied to a fiber are listed below:

- Uniform

where ΔT0 is the constant temperature.

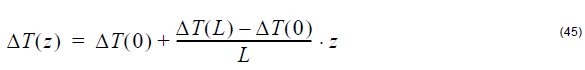

- Linear

where L is the grating length, ΔT(0) is the temperature at Z = 0, and ΔT(L) is

the temperature at z = L.

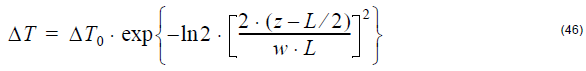

- Gaussian

where ΔT0 is the peak temperature value and w is the normalized value of FWHM.

Other temperature distributions can be defined by user functions.