Designing a fiber profile

The process of designing a new fiber usually starts by defining its profile. Click the

“Fiber Profile” icon in the Navigator pane or double-click the workspace or select the

“Fiber/Profile” menu item.

Currently two types of profiles are supported: refractive index profile and dopant

concentration profile. The “Select Profile Type” dialog box offers a choice between

them.

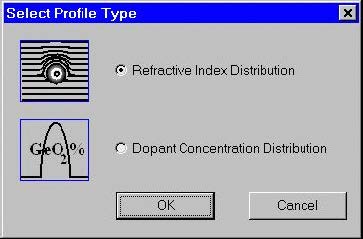

After that the “Fiber Profile” dialog box appears. In case the user has selected

refractive index profile type, it looks as shown:

To create a simple step-index fiber (similar to SMF-28) do the following steps:

| Step | Action |

| 1 | In the “Fiber Profile” dialog box, click the “Add” button twice to create two radial index regions: “Region 0” and “Region 1”. These two regions will represent the fiber core and cladding, respectively. |

| 2 | Select “Region 0” on the list and enter its Width value 4.15 microns, then select the “Profile” option as “Constant”, and enter the “Refr. Index” value 1.45213. |

| 3 | Press “Apply”. |

| 4 | Select “Region 1” on the list and enter its “Width” value 58.35, then select the “Profile” option “Constant”, and enter the “Refr. Index” value 1.44692. |

| 5 | Press “Apply”. |

| 6 | Enter the “Wavelength” value 1.3. |

| 7 | Press “Apply”. |

| 8 | Press “OK” to close the “Fiber Profile” dialog box. |

You just designed a simple fiber profile that is shown at in the graph pane at the

bottom of the dialog box. The fiber profile is defined at the wavelength 1.3 microns.

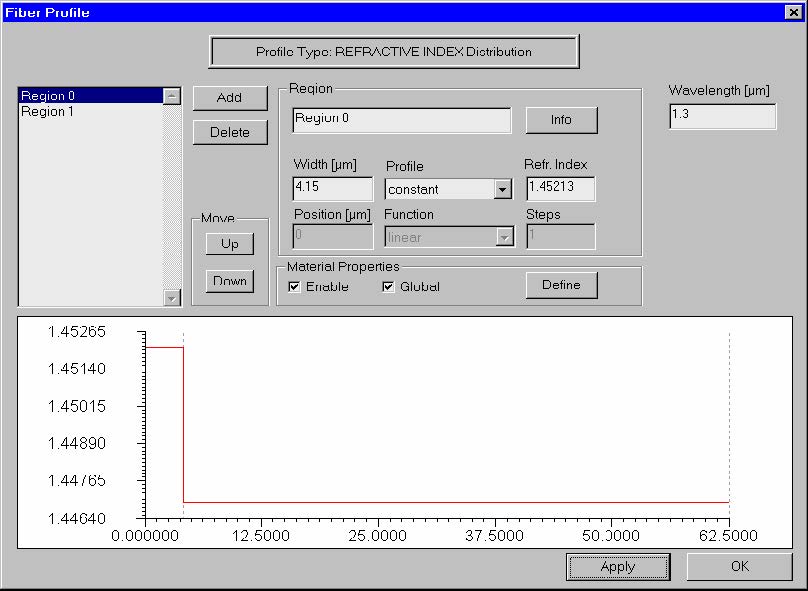

If in “Select Profile Type” dialog box the user has selected “dopant concentration type”

then the ‘Fiber Profile” dialog box looks as shown:

The difference from the previous case is that now the user enters the values of the

molar concentration percentage of the dopant in the edit box where the refr. index

values were entered. This dialog box contains also an additional group of controls –

“Display” – allowing viewing of the profile as a refr. index or concentration type one,

and to color-code the regions. The latter feature is useful for distinguishing

neighboring regions: 1) having equal refr. indices but doped with different

concentrations of different materials, or 2) doped with equal concentrations of

different materials, thus having different refr. indices. The fiber shown in the picture

above is equivalent to the one in the previous picture.