It is generally accepted that the enhanced transmission is mediated by surface

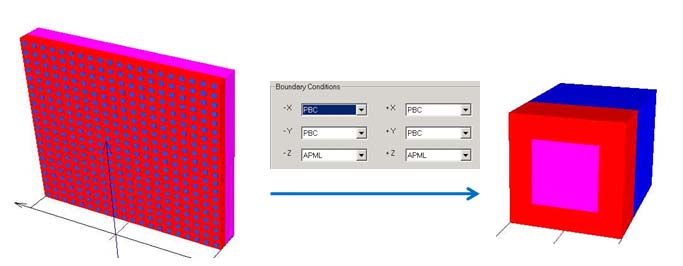

plasmon polaritons (SPPs) that exhibit resonances set up by the periodicity of the array. We will calculate the transmission through sub-wavelength holes in a gold film deposited in SiO2 substrate. Surface Plasmon wave that results from the periodic array of holes will enhance the transmission in a certain wavelength region. The original layout is shown in figure 5. It is periodic square-air-hole arrays that were created by ion milling in optically thick Au films (200 nm) deposited on glass. All arrays investigated have a period of 425 nm. The width of the square holes is varied (148nm, 165nm, 187nm, 196nm, 231nm, 247nm, 286nm). In this simulation the initial input plane wave will propagate to z-direction, so we can just pick up one unit cell for the simulation with x and y boundary set as PBC. This will save the simulation time.

The sample layout can be found in the 64bit sample folder, it is named as “X64_Sample53_HolesInGoldFilm_Pulse500nm_1000nm.FDT”

Figure 4: Original layout and single cell layout

The following will show:

1) How to create the layout with variable.

2) How to setup variable to sweep the hole’s size.

3) How to perform the variable sweep simulation.

Layout Creation steps

| Step | Action |

| 1 | Open OptiFDTD Waveguide layout DesignerFrom the Start menu, select Programs –>Optiwave Software –> OptiFDTD-> Waveguide Layout Designer. OptiFDTD_Designer window opens. |

| 2 | Create a new project.From the OptiFDTD_Designer File menu, select New. The Initial Properties dialog box appears. |

| 3 | Define the material(s) and waveguide profile(s) that will be used in the project.Click the Profiles and Materials button in the Initial Properties dialog.The Profile Designer OptiFDTD opens.Note: At any time, you can open the Profile Designer from the “Edit->Profiles and Materials…” menu of the Layout Designer or from the Start menu. So you can make appropriate modifications to the defined materials and profiles whenever it is needed.

a. In the material folder of Master. Find build in gold material “Gold_Au_Lorentz_Drude_Model”, select this material and drag it to FDTD-Dispersive folder under Materials folder of current project OptiFDTD_Designer1, Click Store button in the Gold_Au_Lorentz_Drude_Model dialog box to save this material to the project. b. In the directory under OptiFDTD_Designer1 of Profile Designer OptiFDTD, under Materials folder, right-click the Dielectric folder. A context menu appears. Select New, the Dielectric dialog box appears.

By default the Isotropic Refractive Index is selected. Type the following information. Name: n=1.5 Isotropic (Re): 1.5 Click Store to save this material, Material n=1.5 will be listed under the FDTD-Dielectric folder (the following sub-step c-d is to design the waveguide cross-section that will be used in the layout. ) c. In the directory under OptiFDTD_Designer1, under the Profiles folder, right click the Channel folder. A context menu appears. Select New. The Channel Profile dialog box appears. Type the following information: • Profile name: Channel_Au • Under 3D profile definition: Type the following information: Layer name: Layer1 Width: 0.425 Thickness: 0.425 Offset: 0.0 • In the Material list, select Gold_Au_Lorentz_Drude_Model • Click Add. • To save the channel profile, click Store. Channel_Au appears in the Channel folder. d. In the directory under OptiFDTD_Designer1, under the Profiles folder, right click the Channel folder. A context menu appears. Select New. The Channel Profile dialog box appears. Type the following information: • Profile name: Channel_Air • Under 3D profile definition: Type the following information: Layer name: Layer1 Width: 0.2 Thickness: 0.2 Offset: 0.0 • In the Material list, select Air • Click Add. • To save the channel profile, click Store. Channel_Air appears in the Channel folder. e. In the directory under OptiFDTD_Designer1, under the Profiles folder, right click the Channel folder. A context menu appears. Select New. The Channel Profile dialog box appears. Type the following information: • Profile name: Channel_SiO2 • Under 3D profile definition: Type the following information: Layer name: Layer1 Width: 0.425 Thickness: 0.425 Offset: 0.0 • In the Material list, select n=1.5 • Click Add. • To save the channel profile, click Store. Channel_SiO2 appears in the Channel folder |

| 4 | Return to Initial Properties dialog box of Waveguide Layout Designer.Either minimize or close the Waveguide Profile Designer. |

| 5 | Type the following information in each corresponding area in Initial Properties dialog box:• Default Waveguide:Width ( μm ): 0.2Profile: Channel_SiO2

• Wafer Dimension Length ( μm ): 1.0 (z-direction dimension) Width ( μm ): 0.425 (x-direction dimension) • 3D Wafer Properties Cladding Material: Air Cladding Thickness: 0.425(y-direction dimension) Substrate Material: Air Substrate Thickness: 0 (y-direction dimension) |

| 6 | Click OK in Initial Properties dialog box. OptiFDTD Designer- [OptiFDTDigner1] window appears.Note:• If not all Toolbars appear in the Layout Desinger window, you can change it from the “View-Toolbars” menu option.

• You can click “+” (zoom) toolbar button to enlarge the layout window. • You can open “Wafer Properties” from the Edit menu to modify simulation domain properties. • Select “Profiles and Materials” from the Edit menu to open the Profile Designer where you can add and modify materials and profiles. |

| 7 | Define a variable that will be used as the hole’s width:• Select Edit Parameters under Simulation menu. Variable and Function dialog box appears• Click User Variable tab, define a variable Name as holewidth, expression as 0.247.

• Click Verify button to check the expression value, click Add/Apply button to add this variable in the list • Click OK to finish the variable definition |

| 8 | Draw the substrate• Select Linear Waveguide shape under Draw menu or form the shortcut toolbar• In the layout window, drag the linear waveguide from the start point to the end point A linear waveguide appears in the layout window.

• Release the Linear Waveguide selection tool by clicking the Select tool after the Linear Waveguide is drawn in the layout. • To adjust the position and the shape of this linear waveguide, double-click on the drawn waveguide. The Linear Waveguide Properties dialog box appears • In the Linear Waveguide Properties dialog box, type the following values: Start horizontal offset: 0.6 (z-direction start) Start vertical offset : 0 (x-direction start) End horizontal offset: 1.0 (z-direction start) End vertical offset : 0 (x-direction start) Channel thickness tapering (waveguide thickness in y-direction) Deselect use default Select taper type as linear Start: 0.425 End: 0.425 Width: 0.425 ( x-direction waveguide thickness) Depth: 0 (waveguide button to the y-direction original point) Label: Linear1 Profile: Channel_SiO2 • Click OK to close the substrate waveguide setting. |

| 9 | Draw the gold film layerAdd a linear waveguide using the previous steps outlined in step 8 and set it’s properties using the properties listed below:Start horizontal offset: 0.4 (z-direction start)

Start vertical offset : 0 (x-direction start) End horizontal offset: 0.6 (z-direction start) End vertical offset : 0 (x-direction start) Channel thickness tapering (waveguide thickness in y-direction) Deselect use default Select taper type as linear Start: 0.425 End: 0.425 Width: 0.425 ( x-direction waveguide thickness) Depth: 0 (waveguide button to the y-direction original point) Label: Linear2 Profile: Channel_Au |

| 10 | Draw the square Air hole.Follow the same manner in step 8 to design the Square Air hole with the following information:Start horizontal offset: 0.399 (z-direction start)

Start vertical offset : 0 (x-direction start) End horizontal offset: 0.6 (z-direction start) End vertical offset : 0 (x-direction start) Channel thickness tapering (waveguide thickness in y-direction) Deselect use default Select taper type as linear Start: holewidth End: holewidth Width: holewidth ( x-direction waveguide thickness) Depth: 0.425/2-holewidth/2 (waveguide button to the y-direction original point) Label: Linear3 Profile: Channel_Air Note: • You can parameterize the waveguide by entering a user-defined variable (parameter) in the Expression field. The expression fields are marked with “fx”. For example you can enter StartPosZ (or an expression like 2*StartPosZ), in the Expression field of Horizontal position definition. Press the Evaluate button, to see the resulting Position value. If the specified parameter has not been defined, the software will prompt you to define it. |

| 11 | Click 3D Layout Model button under the layout window to observe the layout in 3d Mode• Right click and move the mouse will move the graph center• Right click and move the mouse will change the will angle

• Roll the mouse will zoom in and zoom out the graph. |

Design VB script code to Scan the hole width

In the above step 10 we connected the Air hole dimension with the defined variable

“holewidth”, In this section we will use a simple VB code to scan this variable.

| 1 | Click Scripting Button under the Layout window. VB scripting page appears |

| 2 | Copy the following VB code to this page.

Note: The above code has six iterations, each iteration set a defined variable “holewidth” with a new value “dWit” |

| 3 | Click Layout button under the layout window to observe the layout. |

| 4 | Click “Test Script” under Simulation Menu or click Play shortcut toolbar. This will run the VB code. A changing hole size will be observed in the layout window,Note:• VB Script in OptiFDTD is a powerful tool for designing layout, scanning parameters, or even post-simulation analysis. For more details about VB script, please have a look on VB script reference or tutorial lesson15-16. |

Define Input Wave

The Input Wave signal is defined within the Input Plane. To insert the Input Plane and

set the excitation wave, follow the steps below:

| Step | Action |

| 1 | From the Draw menu, select Vertical Input Plane, or select Vertical Input Plane shortcut toolbar (The Vertical Input Plane is in the x-y plane for 3D.) |

| 2 | Click in the layout window at the position where you want to insert the Input Plane. A red line that represents the input plane appears in the layout window. |

| 3 | To set up the Input Plane properties, double-click the red line (Input Plane) in the layout window. The Input Field Properties dialog box appears. |

| 4 | Set the time domain Input Plane basic information.a. a. Select Gaussian Modulated Continuous Wave.The Gaussian Modulated CW tab appears. b. b. Wavelength ( μm ): 0.68( μm ) |

| 5 | Click the Gaussian Modulated CW tab to set the time domain input waveform. The time domain pulse graphics appear. Type the following values for the time domain input planeTime offset (sec.): 0.8e-14Half width (sec.): 0.1e-14

Note: • Right Click on the graph and select the Zoom In tool to enlarge the selected graph region. You can observe the bandwidth in this way. • Adjust half width can adjust the bandwidth |

| 6 | To set up the general information (transverse field distribution) for the Input Plane, click the General tabInput Field Transverse: Rectangular( windowed plane wave)Z Position ( μm ): 0.2Plane Geometry: Positive direction

Label: InputPlane1 (default) |

| 7 | Click 3D Transverse to setup the plane wave setting• Center Position X: 0.0 ( μm ); Halfwidth X: 0.5( μm )• Center Position Y: 0.4125 ( μm ); Halfwidth Y: 0.5( μm )• Effective index: Local

• Polarization: Linear Y • Amplitude: 1.0 (V/m2) |

| 8 | To complete the Input plane setup, click OK. |

Define Simulation Parameters

| Step | Action |

| 1 | From the Simulation menu, select Simulate 3D Using 64-bit Simulator.The 3D Simulation Parameters dialog box appears. |

| 2 | Type the following values for the mesh size:Mesh Delta X (m): 0.005Mesh Delta Y (m): 0.005Mesh Delta Z (m): 0.005 |

| 3 | To set up the boundary condition parameters, click Advanced. The Boundary Conditions dialog box appears.• Set X and Y direction boundary condition as PBC• Set z direction boundary condition as APML

• Type the following values for the PML boundary condition: Anisotropic PML layer number: 20 Theoretical Reflection Coefficient: 1.0e-12 Real Anisotropic PML Tensor Parameter: 70.0 Power of grading Polynomial: 3.5 • Click OK to save changes |

| 4 | Run for 12000 time steps |

| 5 | Time sampling interval: 2 response sample points are used for the spectrum calculation. |

| 6 | Click the “Spectrum” button to set the spectrum range• Set “Number of Samples” to 101,• Uncheck the “Auto” checkbox,

• Check the “Use Wavelength” radio button • Set Start wavelength as 0.5um • Set end wavelength as 1.0um • and press Ok button to accept changes |

| 7 | Click Ok button to accept the specified simulation parameters |

Setup the Observation Objects (result data-detector)

For the 32-Bit FDTD simulation, observation objects will record all the time domain

response so that spectrum analysis can be performed in analyzer. For 64-Bit FDTD

simulation, Observation points will still record all the time domain response in each

single point, but Observation area will perform the spectral analysis in simulator and

save the spectrum DFT results to the analyzer file. For 64bit FDTD simulation, observation Points or Observation Area must be present; otherwise simulations will not store any results for further analysis.

| Step | Action |

| 1 | From the Draw menu (or the shortcut toolbar), select Observation xy plane. |

| 2 | Place the Observation XY Area in the layout. |

| 3 | Double-click the observation XY Area. The “Observation Properties – X-Y Area” dialog box appears. Type the following values in the dialog box:GeneralCenter Horizontal Offset (z-drection): 0.1( μm )Center Vertical Offset(x-direction): 0.0 (μm )

Center depth (y-direction): 0.2125 ( μm ) X-Length Offset 0.425 ( μm ) Y-Length Offset 0.425 ( μm ) Label: ObservationArea1 Data Components Ex, Ey, Hx, Hy |

| 4 | Click OK to close the dialog box |

| 5 | Repeat step 1 to step 4 to designer another Observation area at z=0.1umGeneralCenter Horizontal Offset (z-drection): 0.8( μm )Center Vertical Offset(x-direction): 0.0 (μm )

Center depth (y-direction): 0.2125 ( μm ) X-Length Offset 0.425 ( μm ) Y-Length Offset 0.425 ( μm ) Label: ObservationArea2 Data Components Ex, Ey, Hx, Hy |

| 6 | In the same manner we can put observation point in the layout. |

Perform the VB scripting Scanning 64Bit-FDTD Simulation

| Step | Action |

| 1 | From the Simulation menu, select the “Simulate 3D using 64-Bit Simulator…” option. The 3D Simulation Parameters dialog box appears. |

| 2 | Select “Simulate Using VB script. This will do the VB script scanning simulation |

| 3 | Click Run to start the simulation. The progress window appears, it displays status of the simulations. |

| 4 | Visualization of intermediate simulation results. configure the snapshot settings. In the simulation progress window, select “Simulation ->Take Snapshot” menu option. The “Set Snapshot” dialog box appears• Click Browse button to select the location of the output file• Check the observation areas or observation points. The time domain response in the selected observation objects for the current time-step will be save to the file

• Click OK to close this dialog box |

| 5 | Click the “Take Snapshot” button in the simulation progress dialog box to save the time domain response in the current displayed time step |

| 6 | Go to the folder where the snapshot is saved and with 2D or 3D Viewer observe the time domain response for a certain time stepNote: the simulation may need some time to finish. Simulation is suggested in the off-work time such as in the night so that you can get the results when you come back to work. |

Post-Simulation Data Analysis

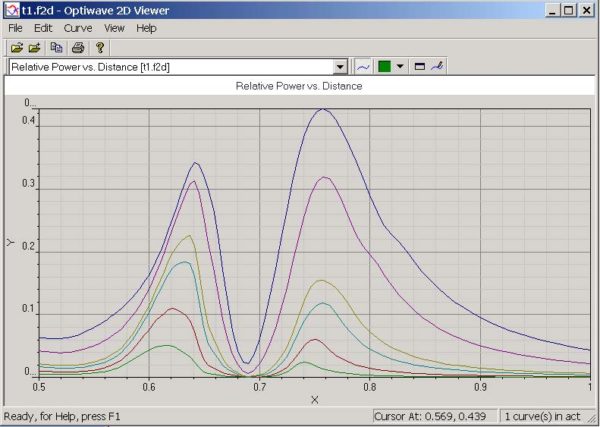

The simulation will generate 6 result files with the extension name as FDA. Open one

result file can observe the field patterns and power transmission/reflection function:

| Step | Action |

| 1 | Select “Observation Area Analysis” under the “Tools” menu in the Analyzer. Select Observation area button to active observation area analysis, Observation Area dialog box appears |

| 2 | Select “ObservationArea2” in the observation area check list |

| 3 | Select wavelength 0.68 from the λ ⁄ f list box |

| 4 | Click Update Graph to observe the field pattern for this wavelength. |

| 5 | Select Power Spectrum button, Power Spectrum dialog box appears, Select total Power “Pz”, Check “Normalize With” checkbox and click Calculate button, PowerTransmission spectrum appears. Click Save As button will save the transmission spectrum to a file |

| 6 | Repeat step 6 for each result file, save the transmission spectrum the different file name |

| 7 | Use OptiFDTD graph tool “Opti 2D viewer” to plot the power transmission spectrum in the same graph• Select “Opti 2D viewer” under Start/All Programs/Optiwave software/OptiFDTD/opti 2D viewer• Select “Add” under file menu to load each exported transmission spectrum file (refer to Figure 5) |

Figure 5: Power transmission spectrum